Quick Navigation

UAX intro

UAX1-4

UAX5

UAX6

UAX7

UAX8

UAX9-11

UAX12

MAX12

UAX13

MAX13

UAX14

UAX Buildings

UAX Forms

|

MAX12

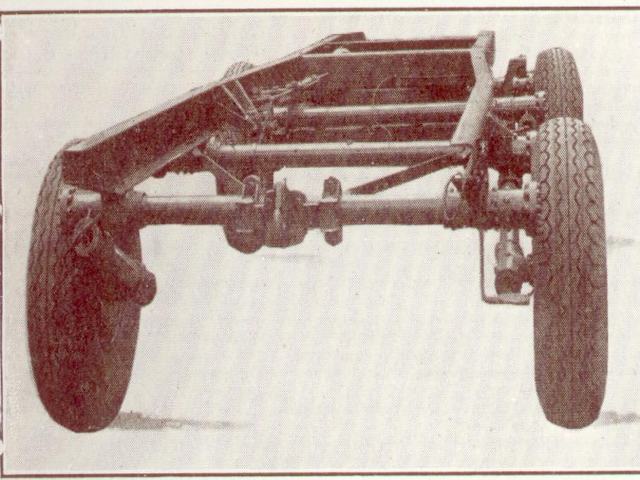

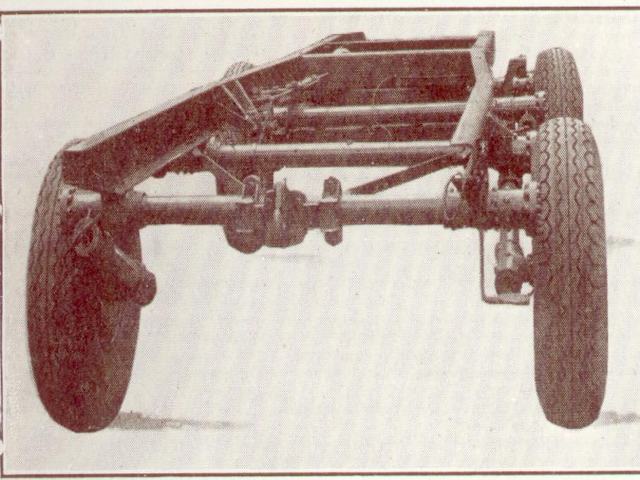

Chassis

The 4-wheel chassis was supplied by J Brockhouse & Co

Ltd, West Bromwich, and is the same as that

supplied to the Royal Air Force for carrying signalling equipment at speed over

rough country. Each wheel is independently sprung by means of a torsion bar.

These bars are about 5’ long and 1 1/8” diameter. They are made from silico

manganese spring steel, oil-hardened and tempered, with an ultimate tensile

strength of 85-100 tons per square inch. Each bar is encased in a tube which

extends the whole width of the chassis and is anchored to the chassis by a

splined sleeve. The other end passes through a bearing and is then splined onto

a tubular crank arm (the oscillating arm), on the end of which is mounted the

stub axle for the wheel. The load on the wheel is taken up by the twisting of

the torsion bar, which provides a very smooth, completely adjustable system of

springing. It also allows the roughest of grounds to be traversed with the

minimum disturbance to the level of the body.

The two front wheels are mounted on a turntable with freedom

to rotate 45 degrees on either side of the dead ahead position. The drawbar is

attached to this turntable, and terminates in a steel coupling eye.

MoT regulations limit the speed of a 4-wheeled trailer to

20mph, and also required that independent control of the trailer brakes, where

positive control by the driver of the towing unit is not provided (over-run

brakes not being permitted on heavy trailers). The independant control is

required on these trailers as it was not known what towing vehicle would be

available. To this end a brakeman’s cabin is provided at the front off-side of

the body. There is a brake lever in this cabin, and also one on the near-side

chassis member (this one for use as a parking brake when manoeuvring by hand).

The brakes themselves are Lockheed hydraulic types, working independently on

all four wheels.

When the vehicle has arrived on site, the road wheels are

replaced by heavy steel feet (normally carried in the body). These feet serve

two purposes: they prevent the tyres from decay, and allow the weight (5 tons

14cwt) to remain on the axles, so preventing the twisting that would occur if

the chassis was packed. The operation of changing the wheels can be done by one

man.

Introduction

General Design

Bodywork

Power Supplies

Telephone Equipment

|